Olive Harvest Methods Harvesting. The best time to harvest fruit for oil is determined according to a maturity index (MI) based on fruit color (Fig, 1,2). Depending on the variety and desired flavor characteristics of the oil, a fruit MI between 2.5 to 4.5 is used (Vossen 2005). Experience will be the best guide in determining the best MI for your particular location. 1  Fig. 1  Maturity index (MI) for olive ripeness.

Maturity Index for Olive Ripeness Olives are traditionally hand harvested, a process that is not only tedious and laborious, but represents the major proportion of the costs of production. Hand harvest is accomplished by three techniques: 1) collection of fallen fruit from the ground, 2) “milking”, or the stripping of fruit with half open hands from limbs which falls into picking bags or onto nets below the tree, 3) beating limbs with large sticks to dislodge fruit, which is also collected on nets. Mechanical harvest of olives has been used to a limited extent in more intensive orchards. 4 US ca 1900

Fig. 3. Workers (some Asian Americans) working jubilantly in an olive grove, Los Angeles. Fig. 4. A man, standing halfway up a ladder, hacks away at the olive branches with a stick. Another man (at right), holding a stick, appears to be shoving the stick into the trees (or against the branches) in order to make the olives fall to the blanket covering the floor beneath the tree. Fig. 5. Worker standing on a ladder leaned against one of the dozen or so trees in an olive orchard, El Toro, California. The orchard is over 100 years old. France

Fig. 6. Oliviers sur la commune de Chateauneuf de Bordette, France Fig. 7. Olive harvest net, near Contes (Alpes-Maritimes, France), in the PDO "Olive de Nice" area (Cailletier cultivar of Olea europaea subsp. europaea) Fig. 8. Usually, olives for oil are harvested when their color is between green and black. It doesn't matter if some olives have been shocked because they are going to be pressed. The comb drop down the olives on a net laid on the soil. Salonenque is one variety allowed for 'Huile de Provence' oil. Fig. 9. Les olivades au Chateau Virant, Provence Alpes Côte D'Azur. Italy

Fig. 10. Olive picking in Montecolognola, Umbria. Fig. 11. La raccolta delle olive si evolve con nuovi macchinari, viene usato abbacchiatore elettrico a batteria. The olive harvest evolves with new machinery, battery-operated electric harvester is used. Fig. 12. Tool used to take olives off a tree (upper right hand corner). Fig. 13. Raccolta olive in Toscana. Greece

Fig. 14. First action is to lay out the olive nets and sheets on the ground. Fig. 15. Some of the olive branches are sawed off, in this way serving both pruning and facilitation of picking. Fig. 16. The branches and some olives have now fallen on the nets. Fig. 17. Handheld mechanical tools are often used to speed up the picking process. Fig. 18. Cut branches are passed through a special harvesting machine to remove and collect the olives. Fig. 19. The olives are gathered into piles by lifting and shaking the corners of the nets. Fig. 20. Olives are transferred to jute or synthetic sacks and loaded onto the pick-up truck, to be carried to the oil press.

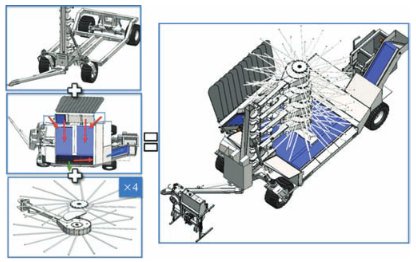

Fig. 21. Olive harvest hand-tool Fig. 22,23. Manual electric olive rake Fig. 24. Electric beater for harvesting olives which exploits the principle vibratory oscillating spheres. Mechanical Harvesting California. Table olives are traditionally harvested manually. However, a shortage of agricultural workers and high labor costs have prompted the search for mechanical solutions. Mechanical harvesting of four cultivars of green table olive—Manzanilla, Hojiblanca, Souri, and Nabali Mouhassan—was compared with manual picking in terms of harvest efficiency and final product quality. Mechanical harvest methods were: trunk shaking with and without simultaneous rod beating and with and without the application of an abscission agent. Olives were immersed in a diluted NaOH solution in the field, transported to the processing plant, and subjected to commercial procedures processing. Application of an abscission agent resulted in inconsistent fruit-detachment force values and did not affect harvest efficiency. Mechanical harvest with rod beating reached high harvest efficiencies of 80% to 95%, whereas the elimination of rod beating significantly reduced harvest efficiency. Final product quality of the mechanically harvested ‘Hojiblanca’, ‘Souri’. and ‘Nabali Mouhassan’ was similar to that of their manually picked counterparts, whereas that of cv. Manzanilla was inferior to those picked manually. High harvest efficiencies can be obtained using trunk shakers and simultaneous rod beating but final product quality of the mechanically harvested olives depends on variety. In some, mechanical harvesting can be used safely; in others such as cv. Manzanilla, further work is required to obtain a good-quality final product. 2 Mechanical harvesting of green table olives can be commercially efficient using today's equipment. The use of abscission agents is not mandatory for obtaining high harvest efficiencies, but the use of rod beating seems to be. Fruit quality of mechanically harvested table olives strongly depends on cultivar. ‘Nabali Mouhassan’ or ‘Hojiblanca’ can be harvested mechanically using the present knowledge in postharvest field treatments. In the case of ‘Manzanilla’, postharvest field treatment must be improved to attain a higher percentage of cannable fruits. 3 Spain. The most widespread orchard category is the traditional one, planted with very large spacing, a low orchard yield (1.1-4.5 t/hm2), multi-trunk trained trees, and large-canopy trees. Harvesting is the most expensive and difficult operation due to the complex tree structure involved, and current commercial systems rely on solutions that are highly conditioned by manual requirements. There is no solution for the integral harvesting, which needs to be economically competitive in terms of time and cost, of the new high-density plantations. The introduction of a harvester may be a key factor in the solution of social and labour issues, as it could compensate for the lack of labour, make some operations less taxing, and reduce labour requirements, costs and harvesting time. Lateral canopy shakers may prove suitable for the integral harvesting of traditional olive trees to simultaneously detach and collect fruit. The wide spacing between trees presents the opportunity to introduce an innovative harvesting process around the tree canopy. However, all of the existing harvesters were designed for work in a row, normally with regular canopies. Consequently, the need exists to design a new harvester for a circular harvesting path around irregular canopies, in conjunction with trees that have been minimally trained beforehand to improve adaptation between machine and tree. The proposed innovation requires research into tree geometry and behaviour in the shaking process, tree training, and machines developed in accordance with the resulting data. The field evaluation aims to demonstrate the viability of integral harvesting applied to traditional olive orchards. These results would offer new alternatives for the modernisation of the olive crop, enhancing crop sustainability and the cultural heritage that the crop represents. 3 The introduction of the innovative circular path harvester (Fig. 26) presented in this paper has shown promising results. It is possible to achieve a mean removal efficiency of 79%-84% with debris similar to that of the available methods. It is highly advisable to perform longer-term tree training to improve the general efficiency of the harvester. The modernisation process in this traditional sector of agriculture will require a great effort and the simultaneous input of researchers, machinery manufacturers and farmers; it should also be taken into account that traditional olive growing is one of the world’s oldest tree crops and is immersed in a culture that is resistant to change. 3  Fig. 25 Most common method (trunk shaker and manual canopy beating) used for harvesting (top) and new method (canopy shaker around the tree) (bottom)  Fig. 26 Design of components (driven system, catch frame and canopy shaker head) and integration in a harvester. Initially, branch shakers and shaker combs facilitated fruit detachment by selecting the bearing branches without modifying the tree structure in crops that were traditionally manually harvested such as olive. Later, trunk shakers enabled detachment of the fruit from the whole tree after modifications had been made in tree structure, such as in olive A third development saw straddle harvesters used for integral harvesting in new, high-density olive orchards that had a different layout, pruned trees and a fully mechanised process. 3

Further Reading Mechanical Harvesting of Table Olives: Harvest Efficiency and Fruit Quality, HortScience pdf Innovative circular path harvester for mechanical harvesting of irregular and large-canopy olive trees, International Journal of Agricultural and Biological Engineering pdf Back to Olive Page |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bibliography 1 Miyasaka, Susan C., et al. "Reflective Guide to Growing Olives for Oil Production in Hawai‘i." College of Tropical Agriculture and Human Resources University of Hawai'i at Mānoa, NPH-16, Jan. 2017, CTAHR, www.ctahr.hawaii.edu/oc/freepubs/pdf/NPH-16.pdf. Accessed 20 Jan. 2020. 2 Zipori, Isaac. "Mechanical Harvesting of Table Olives: Harvest Efficiency and Fruit Quality." American Society for horticultural Science, Vol. 49: Issue 1, Jan. 2014, HortScience, (CC BY-NC-ND 4.0), doi.org/10.21273/HORTSCI.49.1.55. Accessed 19 Jan. 2020. 3 Sola-Guirado, Rafael R., et al. "Innovative circular path harvester for mechanical harvesting of irregular and large-canopy olive trees." International Journal of Agricultural and Biological Engineering, Vol. 11 No.3, May 2018, IJABE, 10.25165/j.ijabe.20181103.3265. Accessed 19 Jan. 2020. 4 Reiger, Mark. Introduction in Fruit Crops. New York, The Haworth Food & Agricultural Products Press, 2006. Video V1 "Speedy 125 Umbrella Olive tree shaker, self-propelled, hydraulic." Sicma International, www.sicmasrl.com/en/machines/item/speedy-umbrella?category_id=85. Accessed 6 Mar. 2020. Photographs Fig. 1,2 "Maturity index (MI) for olive ripeness." Reflective Guide to Growing Olives for Oil Production in Hawai‘i, NPH-16, Jan. 2017, CTAHR, www.ctahr.hawaii.edu/oc/freepubs/pdf/NPH-16.pdf. Accessed 20 Jan. 2020. Fig. 3 "Workers (some Asian Americans) working jubilantly in an olive grove, Los Angeles." California Historical Society Collection, 1860-1960, c. 1900, Wikimedia Commons, Public Domain, commons.wikimedia.org/wiki/Category:Olive. Accessed 16 Jan. 2020. Fig. 4 "Workers in an olive grove, Los Angeles, ca.1900." California Historical Society Collection, 1860-1960, c. 1900, Wikimedia Commons, Public Domain, commons.wikimedia.org/wiki/Category:Olive_harvest#/media/File:Workers_in_an_olive_grove,_Los_Angeles,_ca.1900_(CHS-5353).jpg. Accessed 16 Jan. 2020. Fig. 5 "Worker standing on a ladder leaned against one of the dozen or so trees in an olive orchard, El Toro, California. The orchard is over 100 years old. ca.1900." California Historical Society Collection, 1860-1960, Wikimedia Commons, Public Domain, commons.wikimedia.org/wiki/Category:Olive. Accessed 16 Jan. 2020. Fig. 6 Casamance, Marianne. "Oliviers sur la commune de Chateauneuf de Bordette." Wikimedia Commons, 23 Nov. 2014, (CC BY-SA 4.0), commons.wikimedia.org/wiki/Category:Olea_europaea_orchards_in_Drôme#/media/File:Chateauneuf_de_Bordette_-_oliviers_2.JPG. Accessed 16 Jan. 2020. Fig. 7 Myrabella. "Olive harvest net, near Contes (Alpes-Maritimes, France), in the PDO "Olive de Nice" area (Cailletier cultivar of Olea europaea subsp. europaea)." Wikimedia Commons, 26 Dec. 2005, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Category:Olive_harvest_in_France#/media/File:Filet_Olive_de_Nice.jpg. Accessed 16 Jan. 2020. Fig. 8 Dionysopoulou, Freideriki. "Usually, olives for oil are harvested when their color is between green and black. It doesn't matter if some olives have been shocked because they are going to be pressed. The comb drop down the olives on a net laid on the soil. Salonenque is one variety allowed for 'Huile de Provence' oil." Wikimedia Commons, 19 Oct. 2019, (CC BY-SA 4.0), commons.wikimedia.org/wiki/Category:Olive_harvest#/media/File:Harvesting_of_olives_'salonenque'_with_comb.jpg. Accessed 16 Jan. 2020. Fig. 9 Chateau Virant. "Les olivades au Chateau Virant, Provence Alpes Côte D'Azur." Wikimedia Commons, 3 Nov. 2003, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Category:Olive_harvest_in_France#/media/File:Les_olivades.JPG. Accessed 16 Jan. 2020. Fig. 10 Demeester. "Olive picking in Montecolognola, Umbria." Wikimedia Commons, 29 June 2009, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Category:Olive_harvest_in_Italy#/media/File:Magione_Montecolognola_olive_picking.JPG. Accessed 16 Jan. 2020. Fig. 11 PROPOLI87. "La raccolta delle olive si evolve con nuovi macchinari, viene usato abbacchiatore elettrico a batteria. The olive harvest evolves with new machinery, battery-operated electric harvester is used." Wikimedia Commons, 27 Oct. 2019, (CC BY-SA 4.0), commons.wikimedia.org/wiki/Category:Olive_harvest_in_Italy#/media/File:Raccolta_olive_con_abbacchiatore_ elettrico_a_batteria.jpg. Accessed 16 Jan. 2020. Fig. 12 Klaas `Z4us` V. "Tool used to take olives off a tree." Wikimedia Commons, 17 Nov. 2013, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Category:Olive_harvest_in_Italy#/media/File:Olive_comb.jpg. Accessed 16 Jan. 2020. Fig. 13 PROPOLI87. "Raccolta olive in Toscana." Wikimedia Commons, 25 Oct. 2019, (CC BY-SA 4.0), commons.wikimedia.org/wiki/Category:Olive_harvest_in_Italy#/media/File:Olive_nel_telo.jpg. Accessed 16 Jan. 2020. Fig. 14 Dionysopoulou, Freideriki. "First action is to lay out the olive nets and sheets on the ground." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:2._The_olive_nets.jpg. Accessed 16 Jan. 2020. Fig. 15 Dionysopoulou, Freideriki. "Some of the olive branches are sawed off, in this way serving both pruning and facilitation of picking." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:3.Cutting_olive_branches.jpg. Accessed 16 Jan. 2020. Fig. 16 Dionysopoulou, Freideriki. "The branches and some olives have now fallen on the nets." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:4._Olives_and_branches_on_nets.jpg. Accessed 16 Jan. 2020. Fig. 17 Dionysopoulou, Freideriki. "Handheld mechanical tools are often used to speed up the picking process." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:5._Mechanical_Olive_picking_tool.jpg. Accessed 16 Jan. 2020. Fig. 18 Dionysopoulou, Freideriki. "Cut branches are passed through a special harvesting machine to remove and collect the olives." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:Mechanical_branch_harvester.jpg. Accessed 16 Jan. 2020. Fig. 19 Dionysopoulou, Freideriki. "The olives are gathered into piles by lifting and shaking the corners of the nets." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:7._Olive_harvest.jpg. Accessed 16 Jan. 2020. Fig. 20 Dionysopoulou, Freideriki. "Olives are transferred to jute or synthetic sacks and loaded onto the pick-up truck, to be carried to the oil press." Wikimedia Commons, 2 June 2011, (CC BY-SA 3.0), commons.wikimedia.org/wiki/Olive_harvesting#/media/File:8._Olive_sacks.jpg. Accessed 16 Jan. 2020. Fig. 21 Werner, Manfred (Tsui). "Olive harvest in Archangelos, Rhodes, Greece." Wikimedia Commons, 27 Nov. 2019, (CC BY-SA 3.0), commons.wikimedia.org. Accessed 16 Jan. 2020. Fig. 22,23 "Manual electric olive rake." AgriExpo, www.agriexpo.online/prod/imbriano-srl-169941.html. Accessed 19 Jan. 2020. Fig. 24 "Manual electric olive rake which exploits the principle vibratory oscillating spheres." AgriExpo, www.agriexpo.online/agricultural-manufacturer/olive-tree-shaker-3181.html. Accessed 19 Jan. 2020. Fig. 25 Sola-Guirado, Rafael R., et al. "Most common method (trunk shaker and manual canopy beating) used for harvesting (top) and new method (canopy shaker around the tree) (bottom)." International Journal of Agricultural and Biological Engineering, Vol. 11 No.3, May 2018, IJABE, 10.25165/j.ijabe.20181103.3265. Accessed 19 Jan. 2020. Fig. 26 Sola-Guirado, Rafael R., et al. "Design of components (driven system, catch frame and canopy shaker head) and integration in a harvester." International Journal of Agricultural and Biological Engineering, Vol. 11 No.3, May 2018, IJABE, 10.25165/j.ijabe.20181103.3265. Accessed 19 Jan. 2020. Fig. 27,28,29 "Speedy 125 Umbrella Olive tree shaker, self-propelled, hydraulic." Sicma International, www.sicmasrl.com/en/machines/item/speedy-umbrella?category_id=85. Accessed 6 Mar. 2020. Published 22 Jan. 2020 LR. Last update 6 Mar. 2020 LR |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||